The Science Behind Cricket Bat Design

In the world of cricket, the bat is not just a piece of wood; it is an engineering marvel that significantly affects a player’s performance and game outcomes. Understanding the science behind cricket bat design involves exploring materials, structural engineering, and physics.

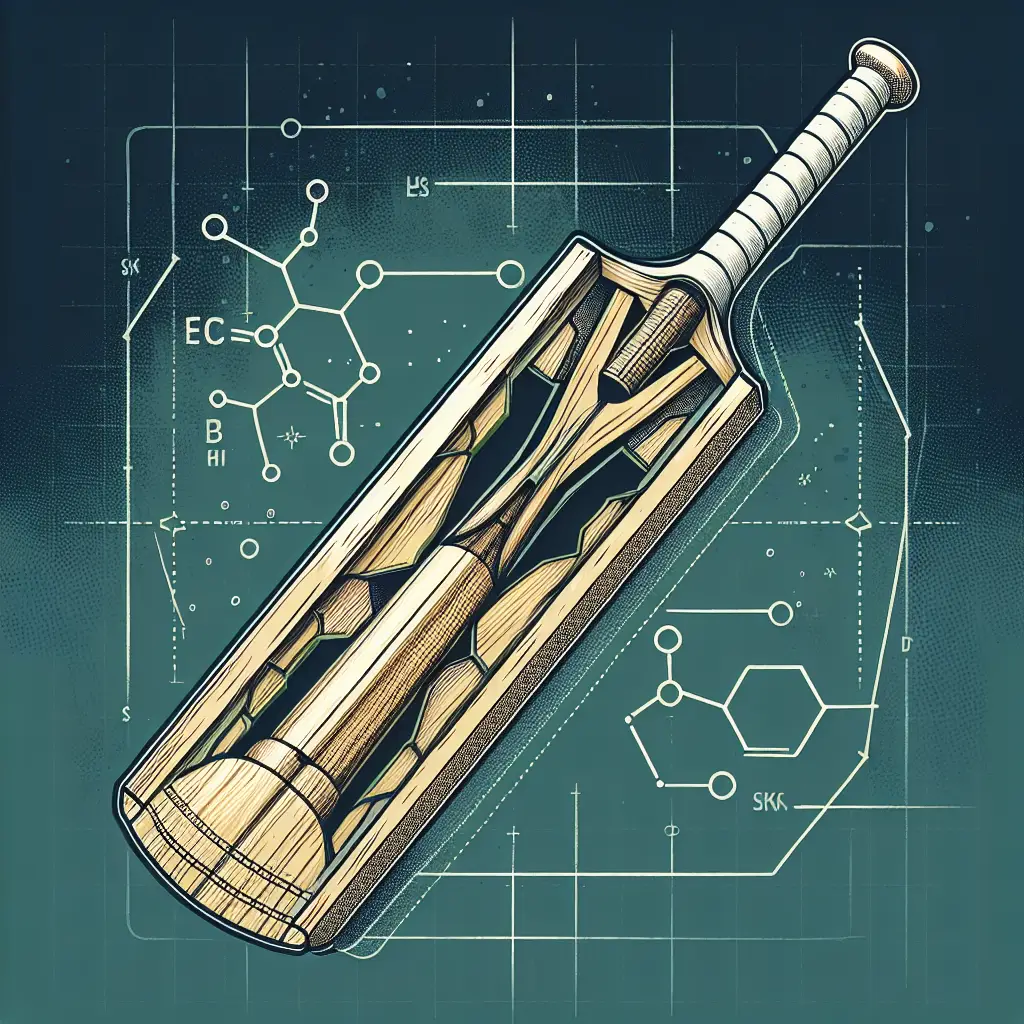

The Anatomy of a Cricket Bat

Before delving into the science of bat design, it’s important to understand the anatomy of a cricket bat. A standard cricket bat consists of several key components:

- Blade: The main hitting surface, typically made from willow.

- Spine: The raised area on the back of the bat that provides structural integrity.

- Face: The flat front surface where the ball makes contact.

- Edges: The sides of the blade that contribute to the bat’s power.

- Toe: The bottom part of the bat that rests on the ground.

- Handle: The part that players grip, often made from cane or other materials for shock absorption.

Material Selection

The choice of materials directly influences a bat’s performance. Traditionally, English willow and Kashmir willow are the two most common materials used for bat production.

English Willow

English willow is favored for its lightweight and resilience. Its fibrous structure provides an excellent balance between strength and flexibility. The wood is harvested from the Salix alba tree, known for its high moisture content. This contributes to durability and shock absorption, making it ideal for professional cricket bats. The wood is subjected to a seasoning process that reduces moisture content, enhancing hardness while retaining its light weight.

Kashmir Willow

Kashmir willow is a more affordable alternative. It may lack the premium quality of English willow but is suitable for beginners and recreational players. While Kashmir willow bats are heavier and less durable, they still offer a good balance for players learning the game.

Other Materials

Recent advances in technology have led to innovations such as carbon fiber and fiberglass in bat manufacturing. These materials offer lightweight and enhanced durability but generally do not provide the same “feel” as traditional wood. Some manufacturers integrate these materials into the handle and toe of the bat to improve shock absorption and overall performance.

Structural Engineering & Design

Understanding the physics behind bat design is essential for optimizing performance. The key principles involve weight distribution, balance, and the sweet spot.

Weight Distribution

The weight of a cricket bat is crucial. Bats can typically range from 1.1 to 1.5 kg. The distribution of weight affects handling and shot execution. Most professional players prefer a bat with more weight concentrated in the blade for power-hitting. This balance can be altered by modifying the spine and edge thickness.

Balance and Pickup

The “pickup” of a bat refers to how heavy it feels while being wielded. A well-balanced bat allows for better maneuverability, critical for effective shot-making. Techniques like tapering the handle and optimizing spine height can improve pickup without increasing overall weight. Manufacturers often measure the pickup using a factory balance point; ideally, it should hover around the player’s sweet spot, the area of the bat that produces maximum power with minimal effort.

Sweet Spot Dynamics

The sweet spot is an area of the bat that maximizes energy transfer upon ball contact. Striking the ball on this spot optimizes power while minimizing vibrations….

Share this content: